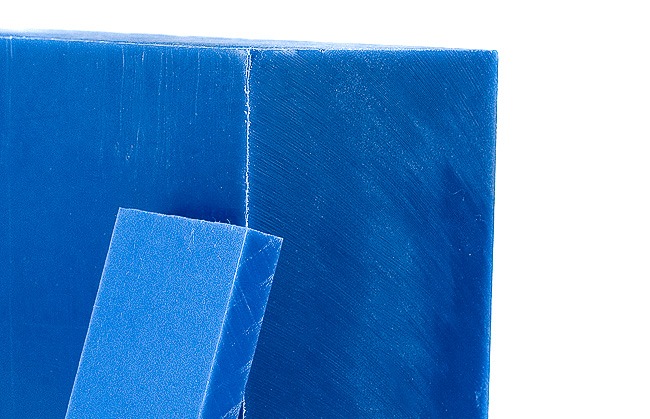

High performance UHMW

Choose the appropriate UHMW for your specific application

High performance UHMW

CIBLER LE BON UHMW EN FONCTION DE VOTRE APPLICATION

Download the UHMW catalog

WHAT IS UHMW?

ARE YOU EXPERIENCING ANY OF THESE ISSUES?

1. Are you facing wear-related issues?

Minimizing metal-to-metal contact is crucial for reducing component wear. TIVAR® 88, a sought-after UHMW material, is favored for manufacturing wear-resistant coatings that are well-suited for extreme environments. Additionally, TIVAR® HPV is an excellent option for conveyor parts, wear strips, and other components that experience high levels of friction.

2. Are you experiencing clogging issues?

Clogging can pose a significant challenge, leading to costly production disruptions. Opting for surface coatings that are specifically designed to address these issues is crucial. For example, in cases where material flow is uneven and bulk materials adhere to chute walls, the application of TIVAR® 88 coatings or liners can effectively minimize clogging and its associated impacts.

3. Are you experiencing excessive noise levels?

Bulk material transportation can result in excessive noise levels, which can be a risk to the health and safety of workers. Installing liners or coatings designed to reduce generated noise is an effective solution. For this type of application, both TIVAR® 88-2 and TIVAR® POLYSTEEL are highly recommended options.

4. Are you facing issues with moisture absorption?

UHMW exhibits an exceptionally low moisture absorption rate and excellent dimensional stability. Its performance remains unaffected by water absorption, even in highly humid environments. TIVAR® 1000 and TIVAR® ECO are well-suited for applications with elevated moisture levels.

5. Are you experiencing excessive maintenance costs?

Utilizing UHMW parts such as TIVAR® CERAM P or TIVAR® HPV helps decrease maintenance costs by increasing the longevity and efficiency of components. In some cases, UHMW parts are employed as sacrificial elements to extend the lifespan of steel parts and assemblies.

ARTICLES DE BLOGUE UHMW

5 APPLICATIONS OF TIVAR® 88

CAN UHMW BE USED IN THE FOOD INDUSTRY?